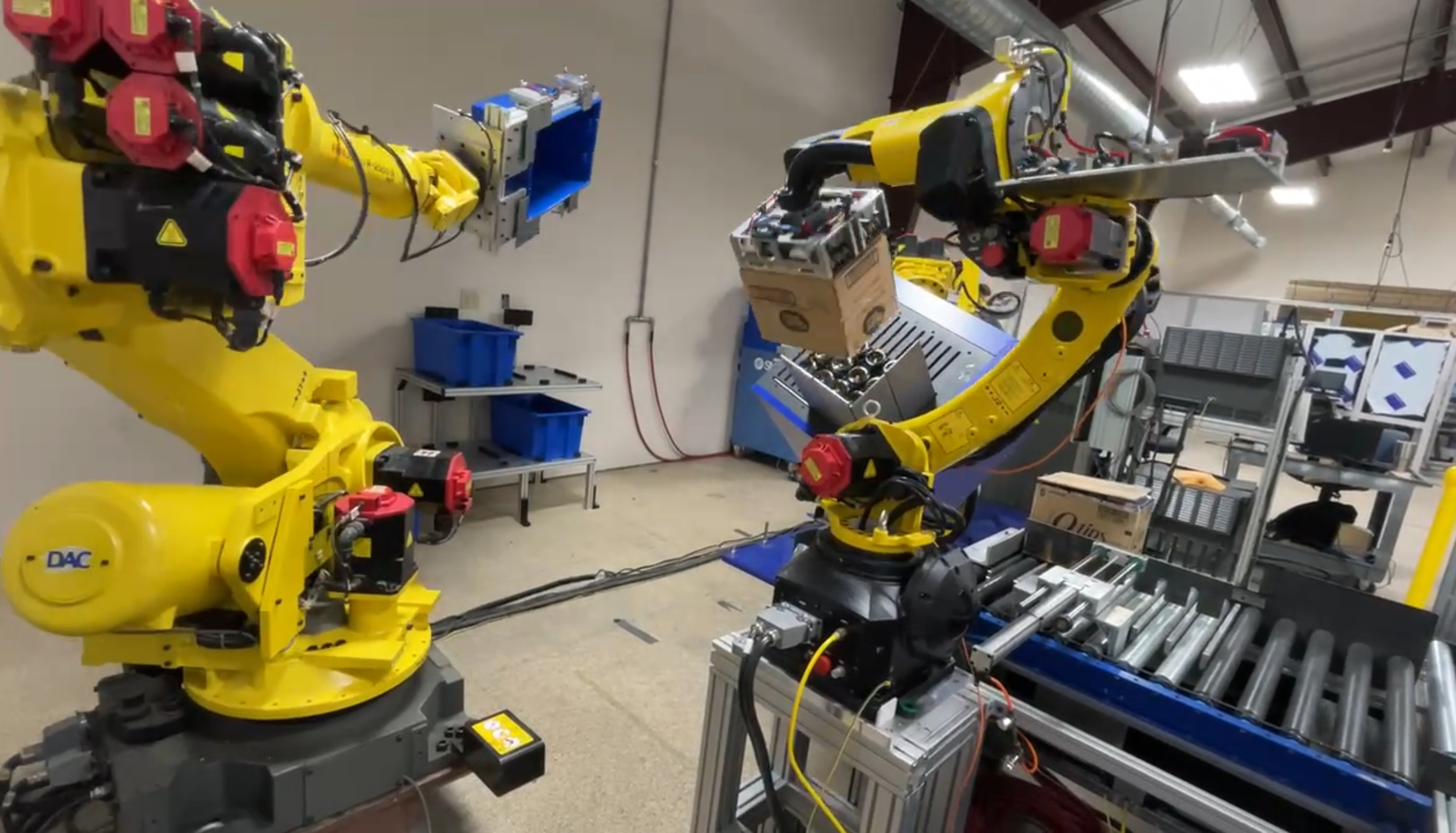

In the fast-paced world of e-commerce and omni-channel fulfillment, efficient box opening and decanting are crucial for maintaining high productivity and accuracy. Our Automated Box Opening and Decant Replenishment system, powered by six-axis robots, intelligent conveyors, and advanced vision systems, offers a comprehensive solution to streamline your receiving, inventory replenishment, and order fulfillment processes.